So you want to use 'green' plastic labware, but the recent news headlines about a UN environmental report has you perplexed… "Biodegradable' Plastics Are A Big Fat Lie". Well, don't panic! Plastic labware can still be a good. It's just important to understand your options. Find out whether the plastic is intended to be biodegraded...or how it can be recycled.

Match your plastic to your disposal service

Let's say you don't have access to the correct recycling program, incinerator, or commercial compositor for disposal. The key would be to purchase biodegradable plastics that are designed to break down in a landfill. The problem of ensuring the quick - as in, less than a year – breakdown, of biodegradable plastics, lies primarily in our ability to get biodegradable plastics to end up in the correct environment. The American Society for Testing and Materials (ASTM) has standards for testing the biodegradability of plastic products in different environments; industrial compost, marine, home compost, anaerobic digestion, active landfill. Unfortunately, the lack of uniformed standards in plastic labeling, makes the task of reaching those necessary end environments improbable (1). The technology for automated sorting is expensive. Until these sorting and labeling problems are solved, it is a good bet to purchase labware designed to biodegrade in an active landfill – since that is where most of it will end up by default.

Bioplastic can be carbon negative

Let's say you do have access to the optimal recycling service. Hooray! In this case the most sustainable option would be a product like Labcon's pipette tip refill system(4) that uses bioplastic polyetholyene. You are covered for the whole life cycle of the plastic.

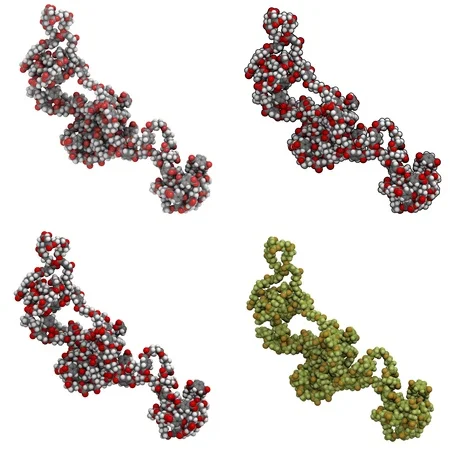

So what is a bioplastic, anyhow? Well, there are over a dozen types of bioplastics. Biopolymers are most often produced either by microorganisms in bioreactors, or in plants that have been genetically engineered with bacterial genes. The biopolymers are then extracted and chemically processed into plastics. Another source for bioplastic is chitosan, which is made from crustacean shells. Researchers from Harvard's Wyss Institute developed chitosan bioplastic. The impact here is that bioplastic is produced from renewable resources. The production of bioplastic actually reduces atmospheric CO². Every bioplastic is not biodegradable, but it is recyclable.

The bioplastic polyethylene used by Labcon is produced by the largest bioplastics manufacturer in the world, Braskem. Braskem makes its bioplastics from sugarcane ethanol. Their Green Polyethylene family of products has had an independent Life Cycle Assessment (LCA) performed. So it's verified that their whole process is carbon negative. This also eliminates the biodegradable labeling and recycle sorting problems. There isn't an issue of biobased plastic being mixed with regular plastics in the same object. Braskem's green plastic can be confidently recycled.

Using green plastic labware has a global environmental impact. Please take a labconscious look at the plastic consumables you are using today,..and what becomes of them tomorrow.

Reference: