Will you take the "-80 Chill Up" Challenge? Learn why your lab should join in this effort to reduce energy consumption.

Read MoreNew UChicago Green Labs Web Site and Glove Recycling

Announcing the UChicago Greenlabs web site! PhD graduate student Erin Fry updates us on their efforts collecting nitrile gloves for Rightcycle.

Read MoreUChicago's Right Cycle Program

Erin is able to work closely with Kimberly-Clarke to set up the RightCycle Program at UChicago - striving to reduce the nearly 20% of lab waste that comes from gloves alone!

Read MoreErin finds success and challenges in addressing recycling campus-wide

Erin conducts an audit to discover what is and what isn't working, begins to build the case for a full time position to tackle sustainability, and contemplates recycling on a campus-wide scale...

Read MoreErin develops a Certification Protocol...

Erin has been working hard to ensure the success of her GreenLabs initiative across campus - she's created a lab EcoLeader position to serve individual labs and make sure they are keeping 75% of the lab's members above the 40% assessment to stay certified!

Read MoreSeeking green lab certification....

As Erin's green labs program has taken hold and demonstrated success, other labs are starting to take notice. Looking beyond her own space, she investigates ways to implement a certification standard that can apply to other interested labs!

Read MoreGreen Lab Build - Implementing Change

Projects focused on energy use reduction, decreased water usage, and overall improvements to waste management start to take shape and activate in the lab!

Read MoreGreen Lab Program is LIVE! Erin's Green Lab Build, Week 12

Green Lab Scientists Coordinating with Facility Managers

Copyright: bakhtiarzein

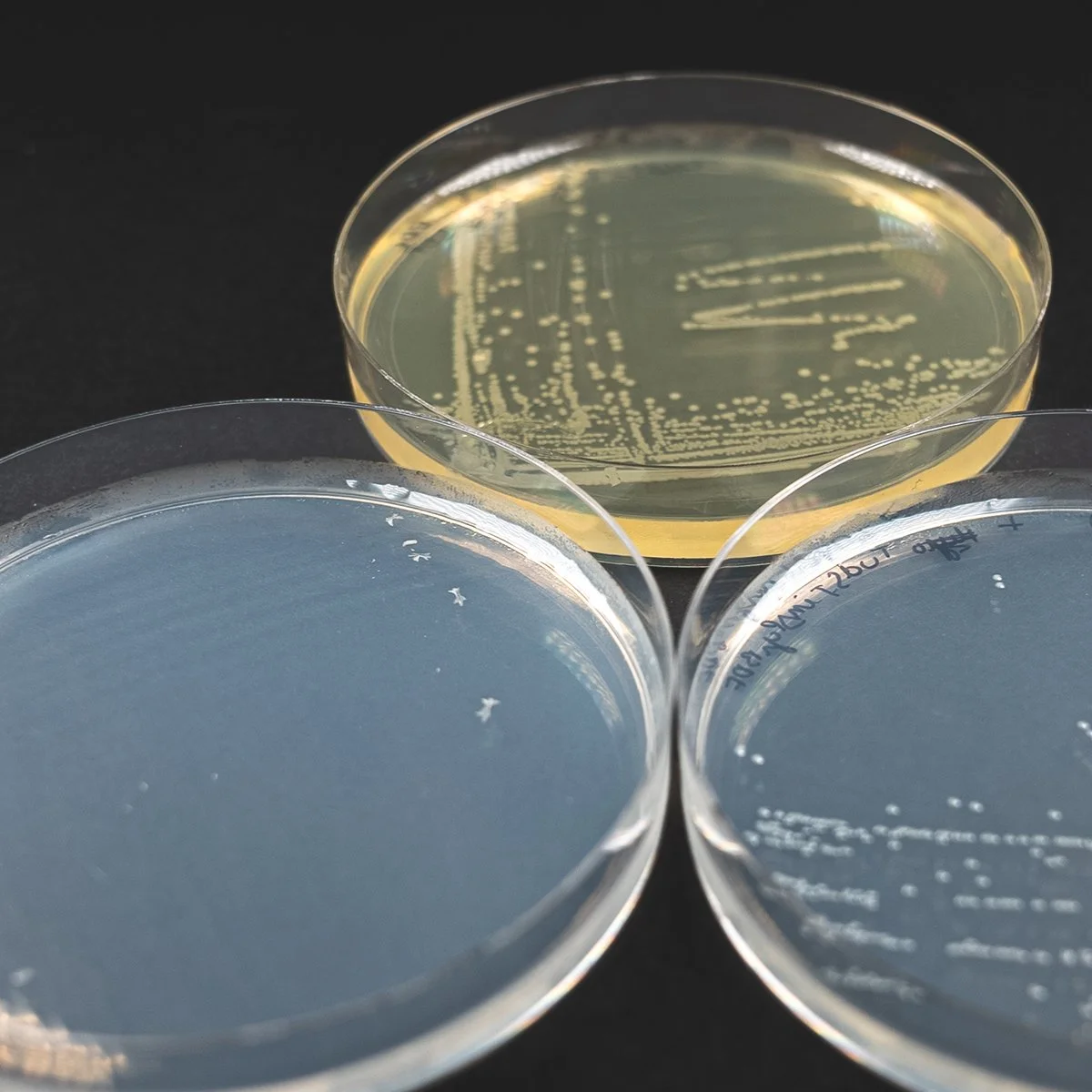

The pilot program is officially off and running! Five laboratories at the University of Chicago are participating, including the Adams, Dolan, Horne-Badovinac, Gounari, and Turkewitz labs. I met with each EcoLeader individually to discuss how I can best help their labs reduce their carbon footprint. There was some variation, although most of the approaches are the same. Additionally, I realized just how important working with facilities would be to not only help these pilot labs, but make any large impact division-wide.

All of the pilot laboratories are within the biological sciences, so there is some degree of similarity between the labs, although their level of initial sustainability was extremely variable. One lab studies flies and much of their materials are reused and processed for them, so waste creation was not a big issue for that lab. Another creates a lot of plastic wrap waste, but collects the wrapping to recycle at the grocery store. Some labs use fume and cell culture hoods all the time, while others do not. One lab was already so good about waste creation and energy reduction that I had to give them extra challenges. Most of the labs were pretty small, but one lab is fairly large with quite a few very passionate individuals to remind other more forgetful lab members to shut the fume hood. A few labs use a lot of tin foil, so we talked about how they can reduce, reuse, and recycle non-contaminated tin foil. I also spoke with each lab about chilling up their ultralow freezers from to -70. They were all fairly receptive to the idea, and a few have already begun chilling up their freezers! Water use was an issue in a few of the laboratories, which was the first sign that facilities services needs to be working with us to make a real impact.

When discussing increased recycling with the laboratories, I discovered that facilities are inadvertently undermining the labs’ previous attempts to be more sustainable. Labs in every building have seen facilities services dump the recycling into the trash, rendering any recycling attempts completely futile until facilities fixes their protocols. I would love to start expanding our efforts, but first our communication with facilities must improve. This was a common theme across many approaches to increase sustainability. The facilities staff turns on the lights overnight and do not turn them off when they are finished. And to top it off, leaking faucets in some buildings are rarely fixed, so a tremendous amount of water is wasted.

GreenLabs has set up a meeting with facilities, including building managers and someone in charge of electricity use. We are hoping to tackle waste disposal, water waste reduction, and electricity use reduction in this meeting. Regarding waste, we would love for facilities to recycle what is in the recycling bins and only replace plastic bags when the bins are full or it is necessary to do so. I hope to work with facilities to install water aerators and improve their response time to leaky faucets. Lastly, there are many simple behavioral cues that can be placed throughout biology buildings that could greatly reduce electricity use in labs, including signage to turn off the lights, use less paper towels, and shut the fume hoods. It would be wonderful if facilities could help GreenLabs distribute these signs to make huge impacts division-wide!

MIT uses a state-of-the-art platform for redistributing lab surplus and a top-notch lab plastic recycling program. MIT research is also at the center of a renewable energy source being deployed to green the grid. It may sound far-fetched, but your future lab could be powered by fuel from seawater.